AI & IoT-Powered

Intelligent Supply Chains

Real-Time Visibility and Predictive Decision-Making

We help transportation companies and fleet operators transform operations through AI-driven insights and IoT-enabled automation — connecting vehicles, warehouses, and control systems into a unified intelligence network.

Rising Costs, Delays & Supply Chain Complexity

Traditional logistics systems rely on manual tracking and reactive responses, leading to inefficiencies that impact your bottom line.

Fuel Volatility

Rising and unpredictable fuel costs impact profitability, demanding data-driven route and consumption optimization.

Delivery Pressure

Growing customer expectations for faster, on-time delivery put immense pressure on logistics networks.

Limited Visibility

Disconnected systems and manual tracking create blind spots across fleets, cargo, and warehouse operations.

Cargo Loss & Spoilage

Risk of theft or spoilage in cold chain shipments during transit due to lack of real-time monitoring.

Vehicle Downtime

Unexpected breakdowns disrupt delivery schedules and lead to high maintenance and repair costs.

Supply Chain Complexity

Managing fragmented global supply chains without predictive analytics leads to reactive and inefficient decisions.

Logistics leaders must move from reactive tracking to predictive, autonomous supply chains to stay competitive.

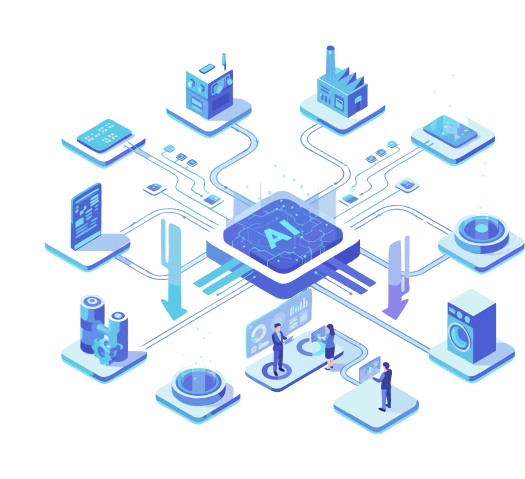

AI + IoT for Connected Logistics Intelligence

Our unified platform connects vehicles, cargo, and hubs to enable proactive fleet management and data-driven supply chain decisions.

Platform Intelligence

IoT devices capture live data on location, fuel, temperature, and vehicle health, while AI models analyze patterns to optimize routes and forecast demand.

We integrate seamlessly with existing ERP, TMS, and fleet management systems to create a unified intelligence layer for your entire operation.

Measurable Impact

Reduced fuel consumption and expenses

Improved on-time delivery rates

Lower vehicle downtime via predictive maintenance

Real-time cargo and asset visibility

Reduced spoilage in cold chain logistics

Enhanced sustainability tracking

Real-World Logistics Automation

Data-driven intelligence across fleets, warehouses, and global supply chains.

Scenario

A logistics company struggles with high fuel costs and delayed deliveries due to inefficient route planning.

Technologies Used

How it works

IoT devices track vehicle state in real time. AI analyzes traffic and schedules to dynamically optimize routes, reducing idle time and fuel consumption.

Outcomes

Scenario

Unexpected vehicle breakdowns disrupt delivery schedules and increase emergency repair costs.

Technologies Used

How it works

Sensors monitor engine health and mechanical metrics. AI models detect early warning signs of failures, enabling proactive servicing.

Outcomes

Scenario

Pharmaceutical and food shipments risk spoilage due to temperature fluctuations during transit.

Technologies Used

How it works

IoT sensors monitor temperature and location throughout the journey. AI analyzed data in real time and alerts operators if thresholds are breached.

Outcomes

Scenario

Warehouses face inefficiencies in inventory tracking and order fulfillment speed.

Technologies Used

How it works

IoT sensors track inventory movement. AI predicts demand patterns and automates replenishment, reducing stockouts and overstocking.

Outcomes

Ready to Transform Your Logistics Operations?

Let's build a smarter, more efficient, and sustainable supply chain together.

Schedule a Logistics Strategy Consultation

Talk to our experts about transforming your supply chain with AI-driven automation.

Request a Demo

See a live demonstration of our fleet management and warehouse intelligence platform.

Speak to a Transportation AI Specialist

Get technical answers about our IoT fleet and supply chain monitoring solutions.